Mechanics and Machine Design

A graduate of Mechanical Engineering field of study obtains knowledge of manufacturing processes, construction and operation of machines. It covers theoretical foundations, expertise and ability to use modern techniques of computer-aided design (CAD / CAM). In addition, each graduate gains knowledge of the organization and management. Thanks to this, young engineer is able to meet different requirements, and in a short time to acquire detailed knowledge required to work at a the given position.

All companies may be places of the potential jobs, whether large, medium and small, because the mechanics appears in all spheres of human activity, ranging from mechanical engineering and electronics to food at the end. Technical knowledge in the range of organization and management allows working in a variety of representations and running their own businesses. Graduates, who wish to devote themselves to scientific work, may take up employment in research institutions, universities or broaden their knowledge in the doctoral program.

Field of study Mechanical Engineering is being implemented at the full-time and part time studies of the I and II degree.

- I degree (Bachelor’s degree) lasts 7 semesters.

- II degree (Master’s degree) last 4 semesters (since 2012, 3 semesters).

- Extramural activities are held during the 10 exits in the semester on Fridays, Saturdays and Sundays. The next two exits are examination ones.

I degree - engineering with majors such as:

- Production Engineering

- Manufacturing Processes

II degree – Master’s degree with majors:

- Biomechanics Engineering

- Production Engineering

- Computer design of machines and processes

- CNC

- Printing Techniques

- Production Engineering of Metals and Plastics

- Weaponry

Production Engineering

Production Engineering specialty offers a widely profiled education. The training program is based on the programs of Production Engineering" Faculties” of the Western countries. The above – mentioned program apart from technical subjects contains a group of subjects in the field of organization, business management and economics.

Graduates of Production Engineering specialties are prepared for such use of their technical and economic knowledge that they obtain the highest economic efficiency while implementing various production tasks, especially, for obtaining high-integration in the relationship of the man - material - machine. The tasks of the production engineer particularly include: the rationalization of activities in all sectors of the economy, industries and individual enterprises, solving problems of technical and economic optimization, planning, business development and cooperation with domestic and foreign partners, solving problems related to product life cycle, cost analysis, analysis of the changing conditions of economic activity.

Subjects lectured at the Production Engineering specialty are: manufacturing techniques including laser technology, business management, business economics, and fundamentals of computer science, automation and control of technical equipment including robotics problems.

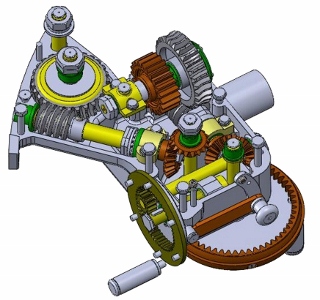

Computer Engineering and Design Processes

Today's innovative products are created usually on the basis of the latest achievements of science and technology, as a result of the cooperation of specialists in many fields such as mathematics, physics, chemistry, mechanics, electronics, computer science, economics and organization of production, with very strong support of computer techniques. Therefore, there is a need to train engineers and technicians who have an understanding of basic disciplines of design, manufacturing and production organization, prepared to solve complex interdisciplinary problems, and are able to use the techniques of computer-aided engineering. The specificity of this specialty is that it includes classes of digital methods of product design (CAD / CAE), technology (CAM) and computer integration of design and manufacturing (CIM).

Students who have such education are technical and computer scientists. They are prepared to work both in industry and in terms of research. They are eagerly sought and employed not only in the country, but also abroad. By appropriate selection of elective subjects, topics, and transitional work thesis students can get an education in one of two profiles: design or technology.

Production Engineering for Metals and Plastics

Students while choosing the specialty of Production Engineeringof Metals and Plastics should have an understanding of the basic techniques of production - their possibilities and limitations. They should also know the material issues and the relationship between structure and properties of the product. During one’s studies, one acquire skills required for computer-aided design of manufacturingprocesses. They are alsocomputer specialists in manufacturing processes. The Faculty is particularly allayed with advancedmaterials processing such as: laser technology, erosion machining, metal forming, precision casting, etc.

Graduates of the specialties are prepared to design and implement new technologies, used in small and large companies to provide high production efficiency, quality and low production costs. They use sophisticated computer systems. They work in manufacturing companies, automotive services, in their own companies and trading companies.

Subjects lectured at the specialty of Production Engineeringfor Metals and Plastics include: selection of materials, micro-technologies, manufacturing techniques including laser techniques, technological equipment, and computer aided proccess planning, production organization.

Printing Techniques

Graduates of printing studies at the Faculty of Production Engineering, Warsaw University of Technology, acquire a broad knowledge of technology, printing and paper industry used in printing materials and methods for their study. In addition, they acquire the ability to use modern computer techniques in the field of processing of images and text, and design processes.

Technologies of Precision and Air Products

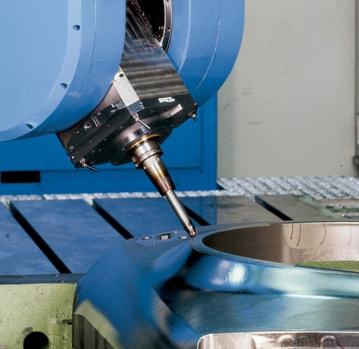

Students choosing a specialty of Technologies of Precision and Air Productsshould generally show a passion for design work, which requires a good knowledge of technical drawing and spatial imagination. You must know the strength of materials and issues to enable the use of computer methods for the design and manufacturing processes.

Graduates are prepared to designing, implementation and operation of machine tools, and automated manufacturing systems, especially the latest generation of computer control, using the actions of various physical effects on the work piece. All design work is currently based on computer systems. Workshops, where classes are held in this specialization include modern computers with specialized software.

Subjects lectured at the specialty of Technologies of Precision and Air Productsinclude: base construction of machine tools, machining and erosion, metal forming, molding and bonding, computer aided process planning, programming of numerically controlled machine tools, production organization.

Weaponry

Important elements of students’ education are a good knowledge of basic subjects, preparation for solving complex interdisciplinary problems, and ability to use computer techniques. Scientific issues related to weapons technology and research work for hundreds of years have been the basis of the development of many fields of technology. The achievements and inventions developed for arms had numerous applications in civil engineering. Graduates’ knowledge in Arms specialties include: basic discipline (the kinetics of combustion, mechanics of movement); external ballistics (flight mechanics, aerodynamics) terminal ballistics (the issue of destruction and deformation). This knowledge is supported by computer aided structural design (CAD / CAM systems, MES and MEB) and the ability to conduct ballistic tests (laboratory tests, and polygonal explosives, ammunition and barrel weapons). It allows you to carry out work on the design, manufacture and testing of weapon systems. It also allows you to carry out work on solutions to the problems of civilian production such as production design and testing of machine tools, automobiles, airplanes, design and implementation of energy systems, pipelines, hydraulic and pneumatic systems, etc.

Graduates find employment in all types of manufacturing plants, research laboratories in the forensic lab, operating centers and scientific - research, as well as trading companies involved in the sale of weapon systems.

Subjects related to the specialty of Weaponry include: internal ballistics, external ballistics, terminal ballistics, construction of weapon systems, weapon system effectiveness, kinematics and dynamics of mechanical systems, mechatronics, design of ammunition, barrel weapons design.

Biomechanics Engineering

Biomechanics Engineering specialty prepares engineers to collaborate with physicians in the design, manufacture medical devices and surgical implants. The specificity of this specialization is the unique combination of typical engineering activities specific to the study at the Faculty of Production Engineering and activities associated with the science of the functioning of the human body, such as anatomy and physiology, biomechanics, biotribology, biophysics, medical imaging.

Second-degree graduate is prepared to:

- Design and manufacture of medical devices, implants and instruments for surgery,

- Supporting equipment for the construction of rehabilitation,

- To participate in research related to biomedical engineering,

- To collaborate with physicians in the use of diagnostic and information systems used in medicine,

- To represent the manufacturers of specialized equipment and medical equipment and rehabilitation.

Mechanics and Machine Design MC

Graduates of Mechanics and Machine Design field of study, specialties in CNC machine tools acquire skills in making use of advanced knowledge in the scope of mechanics, designing, manufacturing and operation of machines and production systems. They gain knowledge of technology of manufacturing machines and products, IT methods supporting engineering works: designing, manufacturing, operation of machine-tools and other machines. They obtain knowledge of employment of automated manufacturing systems in manufacturing technology. CNC machine-tools specialty graduates are in particular prepared for:

-

creative activities related to designing, manufacturing, research and

operating of CNC machine tools as well as machining manufacturing systems, -

developing of manufacturing technologies with aid of CNC machine tool

applying CAD/CAM software using the latest methods (CIM), including

programming of work of technological machines and machine-tools, -

elaborating technological documentation and designing 3D techniques-based

instrumentation processes, managing project data using PDM/PLM systems, - carrying out of model research by methods of computer simulation,

-

designing of operation of stations and machining systems with the use of

robots and industrial manipulators, -

managing and developing of production in electro-mechanical industry,

managing of technological processes, - independently carrying out research in research units,

-

managing of design studios in the scope of construction of machines

and technological processes, - taking creative initiatives and decisions,

- conducting of economic activities on their own,

- continuation of education of studies of the III degree.

Graduates are prepared to work in design, construction and technological units, machine industry enterprises and related industries, scientific-research institutions, research and development centers, consultancy units and in those of dissemination of knowledge in the scope of mechanics, machine design and manufacturing engineering.